Why Transformer Oil Regeneration Is Essential for Effectiveness

Why Transformer Oil Regeneration Is Essential for Effectiveness

Blog Article

Cost-Effective and Eco-Friendly Transformer Upkeep With Regenerated Oil

The integration of regrowed oil in transformer maintenance offers a compelling approach for companies seeking to boost both cost-efficiency and eco-friendliness. By using oil that maintains efficiency requirements comparable to virgin options, services can considerably lower operational prices while all at once lessening their environmental effect. This approach not just addresses the monetary worries connected with waste disposal and regular oil adjustments however additionally adds to more comprehensive sustainability initiatives. The effects of this shift extend past prompt benefits; understanding the complete extent of its advantages needs a closer exam of the concepts and techniques involved.

Understanding Regenerated Oil

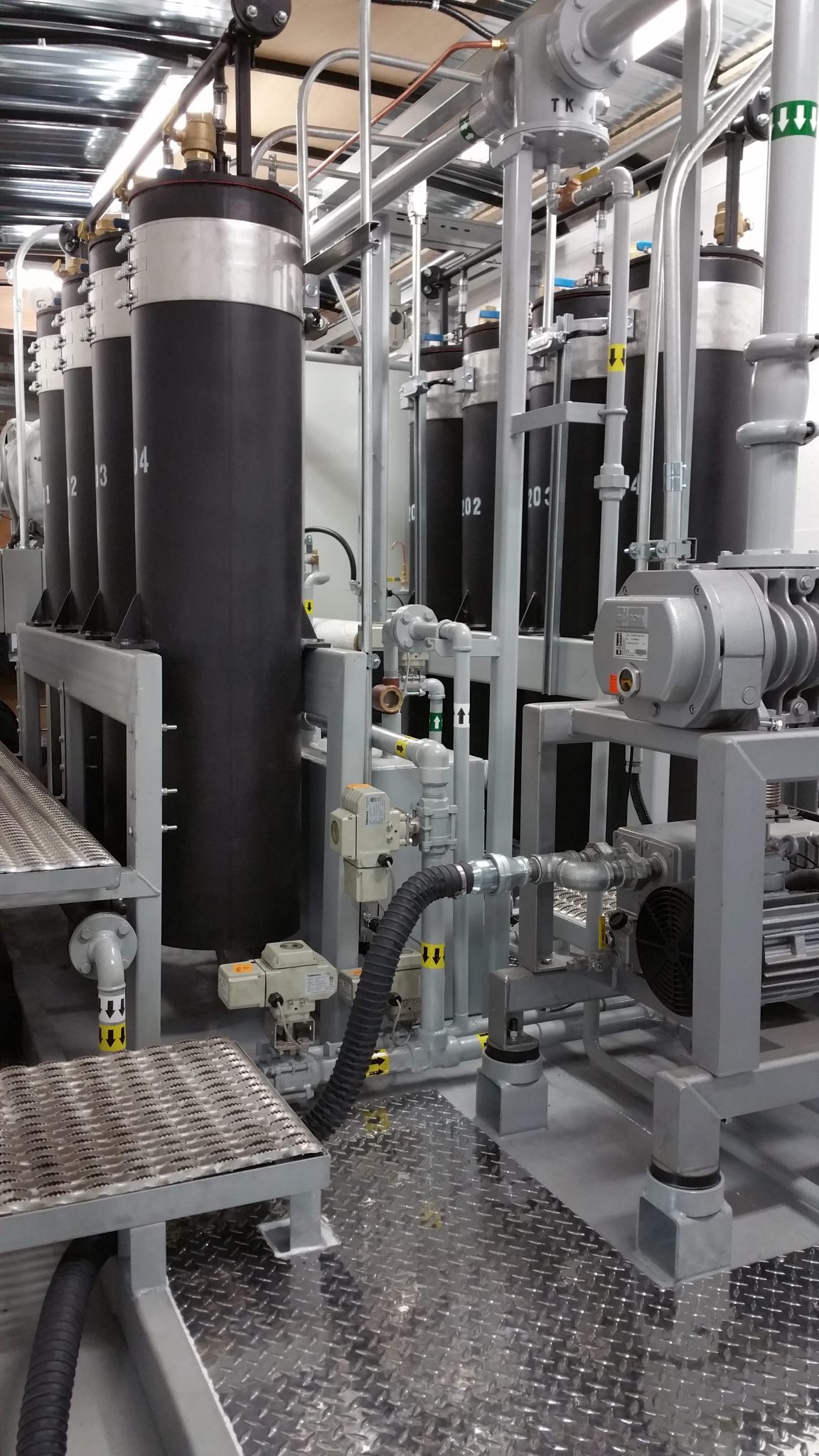

Regenerated oil, commonly described as re-refined oil, is an essential component in the maintenance of transformers, providing both environmental and economic advantages. This oil is stemmed from made use of mineral oils that have undergone a thorough filtration procedure, properly getting rid of impurities and recovering the oil to a top quality equivalent to virgin oil. The regrowth procedure normally includes a number of phases, including physical separation, chemical treatment, and purification, ensuring that contaminations such as sludge, water, and hefty steels are gotten rid of.

The usage of regenerated oil in transformers is essential for maximizing performance and prolonging equipment lifespan. High-quality re-refined oil keeps its dielectric residential or commercial properties, ensuring reliable insulation and stopping electrical breakdowns. In addition, it possesses outstanding thermal conductivity, which aids in managing the functional temperatures of transformers, ultimately improving their reliability and performance.

Additionally, adopting restored oil not only sustains affordable maintenance methods but also reduces the requirement for new oil manufacturing, thereby saving natural deposits. Transitioning to re-refined oil is an intelligent option for organizations aiming to preserve high operational requirements while at the same time taking care of budget restraints. Understanding the properties and advantages of restored oil is important for educated decision-making in transformer maintenance practices.

Ecological Benefits

The use of restored oil in transformer maintenance provides substantial environmental benefits that add to lasting methods within the power sector. Among the key advantages is the reduction of waste oil disposal, as regenerated oil is stemmed from the recycling of used transformer oil, substantially lowering the quantity of dangerous waste produced. This procedure aids mitigate the environmental threats connected with incorrect disposal techniques, which can bring about dirt and water contamination.

Additionally, the regeneration process saves natural deposits by minimizing the requirement for new base oil production - Transformer Oil Regeneration Process. This preservation initiative not just minimizes the removal effect on ecological communities yet additionally decreases the carbon impact related to oil production. By adopting restored oil, firms can enhance their dedication to ecological stewardship and line up with worldwide sustainability goals

Additionally, the usage of regrowed oil enhances the overall efficiency of transformers, leading to decreased energy losses and reduced greenhouse gas emissions. As the energy sector progressively deals with pressure to reduce its environmental impact, embracing regenerated oil represents an aggressive technique to accomplishing both functional and environmental goals. In summary, the ecological advantages of using regenerated oil are diverse, promoting a healthier earth while supporting the energy sector's shift towards sustainability.

Price Cost Savings and Efficiency

Making use of regenerated oil in transformer maintenance can lead to substantial expense financial savings and improved operational effectiveness for energy business. Regrowed oil, generated with sophisticated purification processes, supplies comparable performance to brand-new oil at a fraction of the price. By reusing oil that would certainly otherwise be thrown out, companies can lower their investing in costs while decreasing garbage disposal prices.

Moreover, the extended life process of restored oil translates to lowered frequency of oil adjustments, resulting in reduced labor prices and decreased downtime for maintenance activities. Transformer Oil Regeneration Process. This not only improves operational effectiveness yet also enables an extra structured maintenance routine, making it possible for companies to designate sources more successfully

Furthermore, the use of regrowed oil can bring about reduced insurance premiums because of its environmentally pleasant profile. As energy companies deal with boosting analysis concerning their ecological effect, embracing lasting techniques such as making use of restored oil can strengthen their reputation and potentially attract investment.

Ultimately, the combination of regrowed oil into transformer maintenance practices presents a tactical chance for energy companies to achieve substantial cost savings while promoting functional performance, therefore straightening economic efficiency with ecological obligation.

Comparison With Conventional Oils

While conventional oils have long been the criterion in transformer upkeep, a thorough comparison discloses that regenerated oils supply a number of advantages that enhance efficiency and sustainability. Standard mineral oils, while efficient, commonly position environmental threats, such as contamination and disposal concerns. On the other hand, regenerated oils are originated from recycled materials, dramatically minimizing their ecological footprint.

Among the crucial differentiators is the chemical stability of regenerated oils. They generally exhibit premium oxidative stability, which translates to longer service life and lowered regularity of oil changes. This particular not only boosts transformer efficiency but additionally lessens downtime and maintenance expenses. Additionally, regenerated oils usually consist of reduced levels of harmful ingredients, making them a safer selection for both devices and the setting.

This high quality is crucial in keeping transformer functionality under varying operational conditions. In general, the advantages of regenerated oils over traditional oils highlight their prospective to reinvent transformer upkeep methods, using a much more efficient and accountable alternative.

Application in Upkeep Practices

Once the analysis is full, a customized plan for transitioning to regenerated oil should be developed, taking into consideration elements such as compatibility with existing materials and functional conditions. Training for upkeep workers is vital, as they should understand the unique residential or commercial properties of regenerated oils and how to handle their application successfully.

Implementing a strenuous tracking program will certainly help with the analysis of performance metrics post-implementation, making certain the regenerated oil fulfills the required functional standards. Transformer Oil Regeneration Plant. Additionally, developing a normal maintenance timetable will assist in recognizing prospective issues early and permit punctual corrective actions

Final Thought

Finally, the adoption of regrowed oil for transformer upkeep presents a feasible remedy that aligns economic benefits with ecological sustainability. By reducing costs connected with oil adjustments and waste disposal, while concurrently expanding the lifespan of equipment, organizations can improve functional performance. The change to regenerated oil not only reduces environmental effects yet additionally sustains broader sustainability objectives, making it a prudent choice for modern maintenance methods in the energy industry.

Regrowed oil, commonly referred to as re-refined oil, is an essential part in the upkeep of transformers, giving both ecological and financial Regenerated Transformer Oil advantages. This oil is derived from utilized mineral oils that have actually undertaken a detailed filtration procedure, successfully eliminating pollutants and bring back the oil to a high quality comparable to virgin oil.Furthermore, adopting regenerated oil not just supports cost-efficient upkeep strategies yet additionally minimizes the requirement for new oil manufacturing, therefore saving natural sources. One of the key advantages is the reduction of waste oil disposal, as regenerated oil is acquired from the recycling of made use of transformer oil, substantially reducing the volume of dangerous waste created. Restored oil, created through innovative filtration processes, supplies similar performance to brand-new oil at a fraction of the price.

Report this page